Road Shot Blasting Machine

-

Home >>Road Shot Blasting Machine >>

1、Mobile Shot Blasting Machine:

It can completely remove the accumulated fine particles on the surface of

concrete and purify the impurities found in the material, and undertake

treatment on the surface of concrete, make its surface well-distributed

roughness, greatly improve the adhesive strength of the waterproof layer and

concrete base layer, and at the same time the crack of concrete can be fully

exposed, have the effect of nip in the bud.

Floor Blaster: Road Blaster is used for the construction and maintenance of

roads and bridges. Shot blasting technology is widely used in bridge

anti-corrosion, road roughening, removing road marks, clean paint film and rust

from steel plate etc. The whole process of blasting is dust-free, moveable and

has high productivity.

For Concrete: road blaster | concrete floor shot blaster is used to remove

impurities and laitance layer from concrete; also it can roughen the concrete

and create the uniform roughness which can improve the adhesive force between

water proof layer and concrete layer; also it can fully expose or reveal the

cracks of concrete.

For Steel: The surface of the steel must be sandblasted before primer coating

the steel plates in the steel bridge or oil tank. By shot blasting, the surface

quality of steel can reach Sa2.5/Sa3.0 and get certain roughness, which can meet

the requirements of coating. The whole blasting process is dust-free and

moveable.

Working Principle:

The blasting turbine on mobile road blaster | concrete floor shot blaster

will hit the surface of concrete or steel plate through steel shots. The mixture

of steel shots, dust and other impurities will rebound via rebound pipe

separators. The separators will separate the steel shots and dust, impurity via

dust removing systems. Qualified steel shots will be placed in the storage bin

for recycling. Dust and other impurities will go from air to dust collector.

The shot blaster is equipped with dust removal system. During the blasting

process, it can reach dust-free and pollution-free levels, which not only

improves productivity but also protects environment.

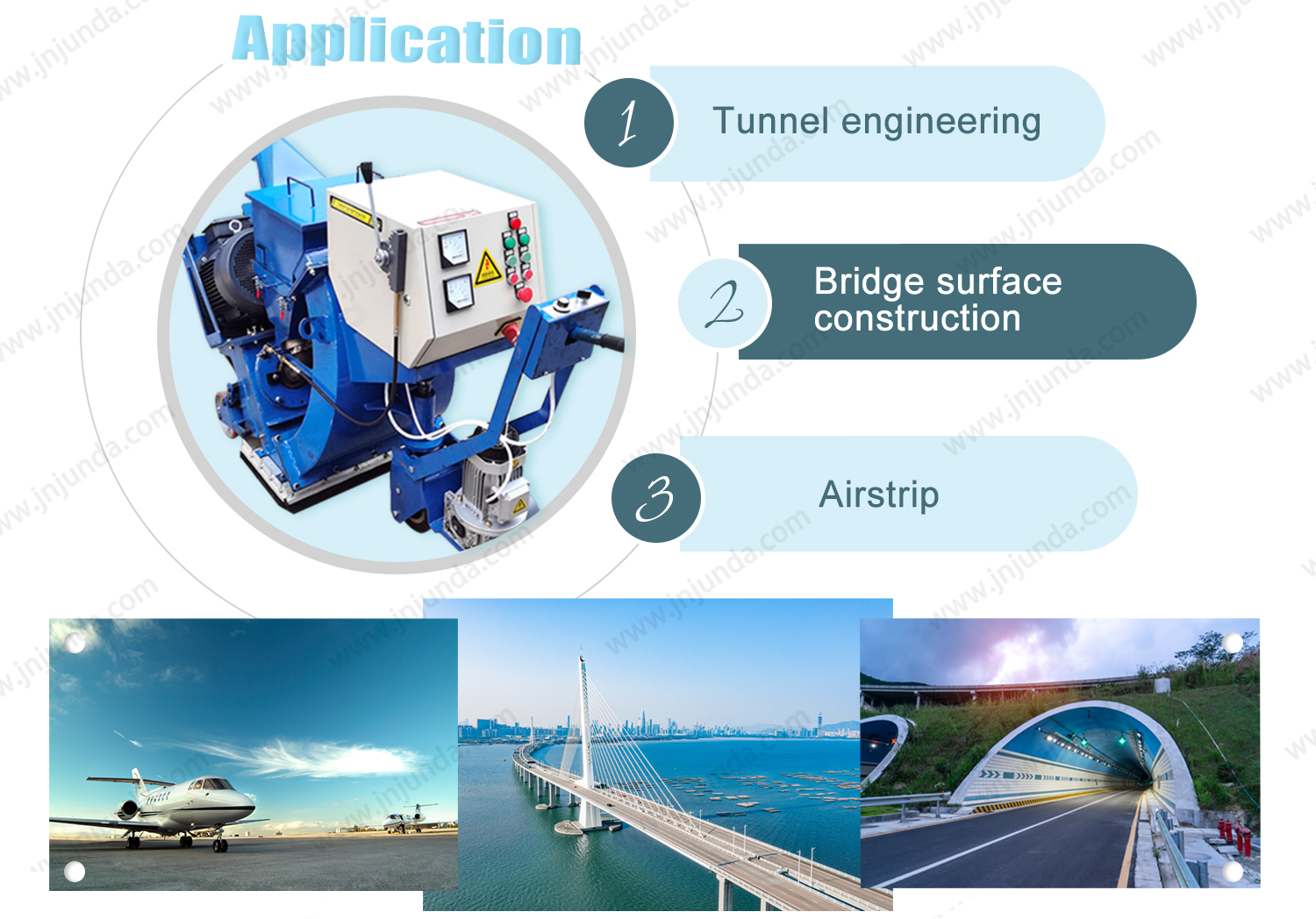

Application

- Improve the roughness and friction factor of asphalt pavement, improve the

adhesion of road and ensure driving safety.

- To do blasting cleaning to steel structure bridge, oil tank and ship deck.

After blasting, it can reach Sa2.5/Sa3.0which is good for painting.

- Tunnel Road Maintenance

- Airport runway preventive maintenance: remove tire marks of air planes, road

markings, improve adhesive force, roughness and friction factor of airport

runway.

- Municipal Road: remove tire marks, road markings, improve adhesive force,

roughness and friction factor ofmunicipal road.

2、Shot blasting machines can be divided into hand-push type, vehicle-mounted

type and white line type according to the walking mode. Shot blasting method is

mainly used for cleaning the marking of cement concrete pavement, especially

suitable for the cleaning of normal temperature.

Its characteristic is that after shot blasting, the friction coefficient of the

road surface will increase, which is beneficial for driving safety, and the

cleaning operation will not produce a large amount of dust. Especially suitable

for cleaning sidewalks near old urban roads.

The advantages of concrete pavement shot blasting machine

The road surface shot blasting machine floats and grinds the concrete surface to

remove impurities. It can perform more than ten surface treatments on the

concrete surface, making the surface uniform and rough, greatly improving the

bonding strength between the waterproof layer and the bottom layer of the

concrete, making the waterproof layer better bond with the bridge deck, and

fully exposing cracks in the concrete.

The pavement shot blasting machine is the best method for cleaning road surface

waterproofing pre-treatment. Thoroughly solved the shortcomings of high dust

emissions and poor effectiveness in previous road construction coatings. At

present, many places have incorporated this construction method into the

acceptance standards. The concrete pavement shot blasting machine is very

practical, ensuring the safety of road and bridge engineering.

After adopting the closed road mobile shot blasting machine technology, the

surface is clean and pollution-free, with uniform roughness, greatly increasing

the bonding contact area between the waterproof layer material and the bridge

deck, achieving the bonding strength and shear strength between the waterproof

material and the substrate. The optimal combination to ensure the service life

of bridge deck pavement. The bridge deck treated with shot peening is suitable

for waterproofing construction of various materials such as waterproofing

membranes, permeable crystalline waterproofing materials, polymer modified

asphalt distributors, rubber asphalt waterproofing intermediate layers, etc.

Application range of road shot blasting machine:

1. Surface treatment of shot blasting machine for concrete bridge deck.

The Closed circuit shot blasting process can clean up and remove the floating

slurry and impurities on the concrete surface at one time. The most important

thing is that the concrete surface is roughened at the same time to make the

surface uniform and rough, which greatly improves the bonding strength of the

waterproof layer and the concrete base layer. And in this process, the shot

blasting process can fully expose the concrete cracks and other diseases, so

that remedial measures can be taken in advance. Can the road shot blasting

machine be constructed on rainy days? No, because steel shots cannot be

recovered on rainy days, and the steel shots may become lumps or damage the

equipment.

The concrete bridge deck is treated by shot blasting technology:

Clean, tidy and rough surface without additional cleaning;

Will not damage the base layer or cause loosening of aggregates in the original

base layer; Good and uniform surface roughness;

Completely and evenly remove surface scum and sand layer; Meet the requirement

of a certain explicit rate;

Greatly improve the bonding strength ofthe waterproof layer;

Suitable for the paving of various waterproof coatings, coiled materials, and

modified emulsified asphalt;

At the same time, the shot blasting technology has high work efficiency when

processing the concrete bridge deck without causing environmental pollution to

the surrounding environment, which is in line with the current national policy

of energy saving, consumption reduction and environmental protection.

Through comparison, it can be considered that a medium, uniform, flat and clean

surface of the bridge deck is the best interface to improve the bonding strength

and shear resistance of the

bonding material to the bridge deck. Therefore, the shot blasting technology is

relative to my country’s treatment of concrete bridge decks. Traditional

technology is highly advanced and economical.

The pavement portable shot blasting machine can solve the defects of the

concrete surface treatment. It can clean up the floating slurry and impurities

on the concrete surface at one time, and can roughen the surface of the concrete

to make the surface uniform and rough, which greatly improves the waterproofing

The adhesive strength of the layer and the concrete base layer can better

combine the waterproof layer and the bridge deck. At the same time, it can fully

show the cracks ofthe concrete and play a preventive role.

| Type | JD-270 | JD-550 | JD-850 |

| Shot blasting wheel diameter | Single 200mm | 550mm | 800mm |

| working width | 270mm | 550mm | 800mm |

| Walking speed | 0.5-20m/min | 0.5-33m/min | 0.5-33m/min |

| Concrete surface cleaning efficiency | 180m2/h | 400m2/h | 600m2/h |

| Steel plate surface cleaning efficiency | 40-50m2/h | 80-100m2/h | 120~160m2/h |

| Dust removal link pipe diameter | 120mm | 150mm | 150mm |

| Recommended steel shot diameter | 1.2-15mm | 1.5-1.8mm | 1.5-1.8mm |

| Matching dust collector | Six-core automatic backflush vacuum cleaner | Eight-core automatic backflush vacuum cleaner | Twelve-core automatic backflush vacuum cleaner |

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

Building A.B.C ,Ouyadaguan Commercial Capital, No.67 Yangguang Xin Road, Shizhong District,Jinan City, Shandong Province, China

0086-531-82020205

+0086-15806668333