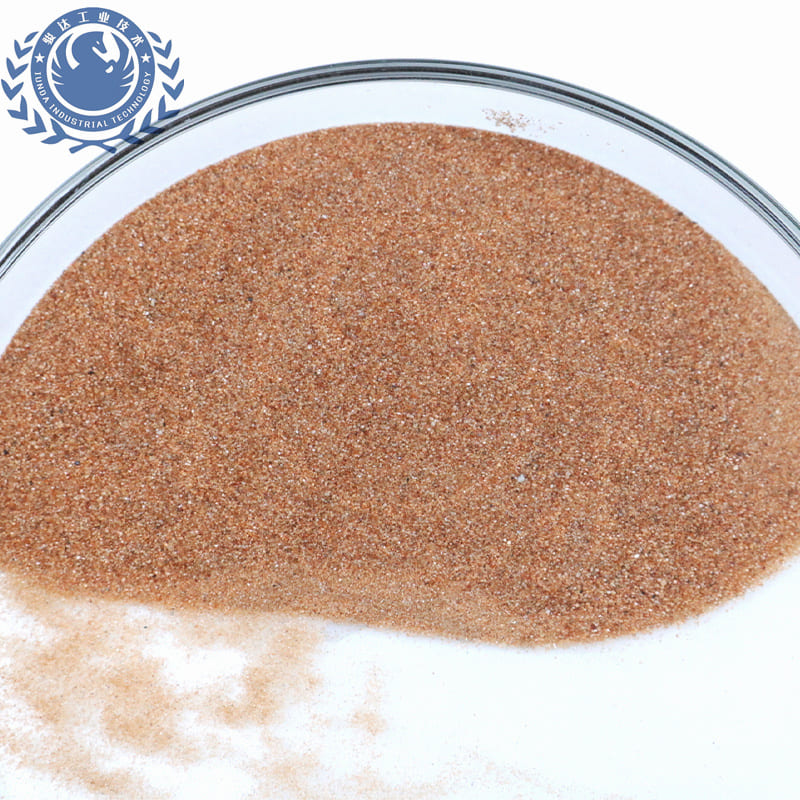

Zircon Sand

-

Home >>Abrasive Media >> Copper Slag

Product introduction

Zircon sand (zircon) is extremely resistant to high temperatures, and its

melting point reaches 2750 degrees Celsius. And resistant to acid corrosion. 80%

of the world's production is directly used in the foundry industry, ceramics,

glass industry and the manufacture of refractory materials. A small amount used

in ferroalloy, medicine, paint, leather, abrasives, chemical and nuclear

industries. Very small amounts are used for smelting zirconium metal.

Zircon sand containing ZrO265 ~ 66% is directly used as the casting material of

iron metal in the foundry because of its melting resistance (melting point above

2500℃). Zircon sand has lower thermal expansion, higher thermal conductivity,

and has stronger chemical stability than other common refractory materials, so

high-quality zircon and other adhesives together have good adhesion and are used

in the casting industry. Zircon sand is also used as bricks for glass kilns.

Zircon sand and zircon powder have other uses when mixed with other refractory

materials.

Product use

Zircon sand (zircon stone) is used in the production of refractory materials

(called zircon refractories, such as zirconium corundum bricks, zirconium

refractory fibers), casting sand (precision casting sand), precision enamel

appliances, and glass, metal (sponge zirconium) and zirconium compounds

(zirconium dioxide, zirconium chloride, sodium zirconate, potassium fluozirate,

zirconium sulfate, etc.). Can make glass kiln zirconia bricks, zirconia bricks

for steel drums, ramming materials and castables; Adding to other materials can

improve its properties, such as adding zirconium sand to synthetic cordierite,

can broaden the sintering range of cordierite, but does not affect its thermal

shock stability; Zirconium sand is added to high alumina brick to make high

alumina brick resistant to spalling, and the thermal shock stability is greatly

improved. It can also be used to extract ZrO2. Zircon sand can be used as

high-quality raw sand for casting, and zircon sand powder is the main component

of casting paint.

Junda Zircon sand | ||||||||||

| Model | Leadingindicator | Moisture | Refractive index | Hardness(mohs) | Bulk density(g/cm3) | Application | ,Melting point | Crystal state | ||

| ZrO2+HfO2 | Fe2O3 | TiO2 | 0.18% | 1.93-2.01 | 7-8 | 4.6-4.7g/cm3 | Refractory materials, fine casting | 2340-2550℃ | Square pyramidal column | |

| zircon sand66 | 66%min | 0.10%max | 0.15%max | |||||||

| zircon sand65 | 65%min | 0.10%max | 0.15%max | |||||||

| zircon sand66 | 63%min | 0.25%max | 0.8%max | |||||||

RECOMMEND PRODUCTS

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333