Stainless Steel Shot

-

Home >>Cut Wire Shot >> Zinc Cut Wire Shot

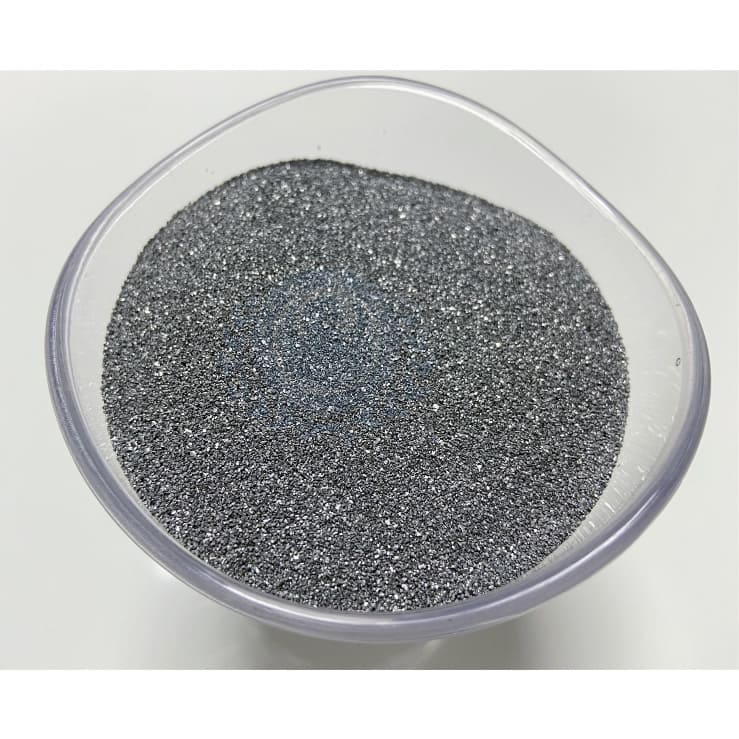

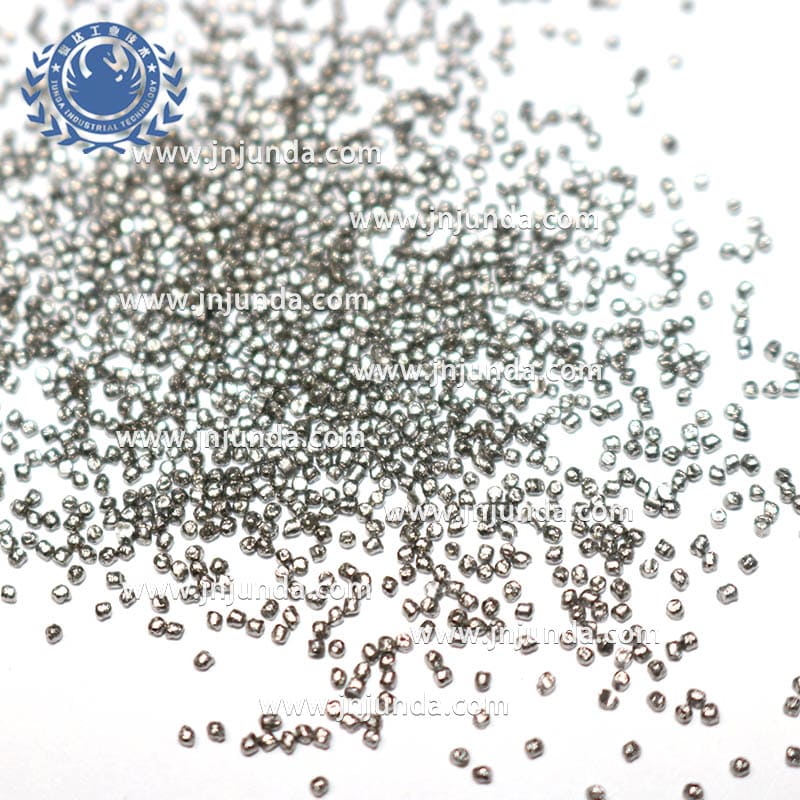

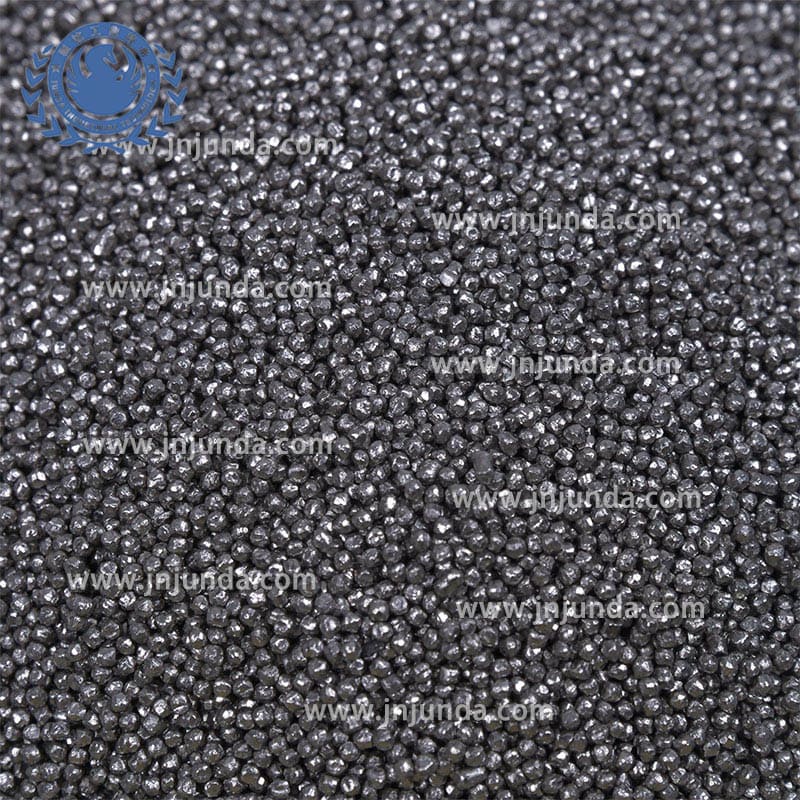

It is produced by German atomization technology and mainly used for sandblasting on the surface of aluminum profiles. The product has the advantages of bright and round particles, less dust, low loss rate and wide spray coverage. Greatly reduce the production cost of aluminum profile enterprises

Application:

It is mainly used for deburring and surface finishing of aluminum die casting, zinc alloy die casting and magnesium alloy die casting; surface finishing of precision casting, stainless steel casting and landscape block; glass making, surface cleaning and various pretreatment of die casting mould.

Specialty:

Compared with stainless steel shot, Tonghua atomization method has no prominent edges and corners, and does not need to worry about the sudden increase of surface roughness when adding shot materials. The product has complete styles.

Scope of application:

1. Surface finishing of aluminum zinc die casting and surface cleaning of aluminum sand casting. The surface of artificial marble is sprayed and polished. Cleaning and finishing of high alloy steel casting surface oxide scale, aluminum alloy engine block and other large die casting parts, marble surface effect treatment and antiskid treatment

2. Aluminum zinc die casting, surface cleaning of precision casting, surface roughening before special coating, refined spray polishing of aluminum profile to remove surface extrusion lines, refined spray polishing of copper aluminum pipe surface, and refined spray polishing of stainless steel container and valve.

3. Clean up the cold casting tools, chromium plating dies for forging dies and tires, renovate the pump cover of automobile engine supercharger, strengthen the precision gear and spring of starter, and spray polishing the surface of stainless steel container.

4. Aluminum zinc die casting, motorcycle engine box, cylinder head, carburetor, engine fuel pump shell, intake pipe, car lock. The surface of low pressure die casting wheel profile shall be cleaned and finished before painting. Surface finishing and cleaning of copper aluminum stainless steel stamping parts, investment casting stainless steel parts, etc.

| Project | 304 Quality | 430 Quality | |

| Chemical composition% | C | 0.08-1.0 | <0.2 |

| Si | 0.4-1.2 | <1.5 | |

| Mn | 0.35-1.2 | 0.8-1.2 | |

| S | <0.05 | <0.05 | |

| P | <0.05 | <0.05 | |

| Cr | 15-16.5 | 15-17 , | |

| Ni | 5-8% | 0 | |

| Hardness | HRC40-50 | HRC35-50 | |

| Density | 7.00 g/cm3 | ||

| Microstructure | austenitic | Ferrite | |

| Appearance | Spherical Hollow particles=0% Hollow particles=0% | ||

| Type | 14-18# / 16-20# / 20-25# / 25-30# / 30-40# / 40-70# / 70-140# / 140-270# | ||

| Packing | Each ton in a separate Pallet and each ton divided in 25KG packs . | ||

| Durability | 27000~28000 times | ||

| Density | 7.0g/cm3 | ||

Application | It is mainly used for deburring and surface finishing of aluminum die casting, zinc alloy die casting and magnesium alloy die casting; surface finishing of precision casting, stainless steel casting and landscape block; glass making, surface cleaning and various pretreatment of die casting mould. | ||

Application

| TYPE | Recommended scope of use |

| 14-18# | Clean up the cold casting tools, chromium plating dies for forging tires, renovate the pump cover of automobile engine supercharger, strengthen the precision gear and spring of starter, and spray polishing the surface of stainless steel container. |

| 16-20# | Aluminum zinc die casting, surface cleaning of precision casting, surface roughening before special coating, refined spray polishing of aluminum profile to remove surface extrusion lines, refined spray polishing of copper aluminum pipe surface, and refined spray polishing of stainless steel container and valve. |

| 20-25# | Aluminum zinc die casting, motorcycle engine box, cylinder head, carburetor, engine fuel pump shell, intake pipe, car lock. The surface of low pressure die casting wheel profile shall be cleaned and finished before painting. Surface finishing and cleaning of copper aluminum stainless steel stamping parts, investment casting stainless steel parts, etc. |

| 25-30# | Aluminum zinc die casting surface finishing, aluminum sand casting surface cleaning. The surface of artificial marble is sprayed and polished. |

| 30-40# | In addition to wg40 function, the surface of stainless steel casting is smooth and fine. Descaling treatment of alloy steel forgings. Artificial marble surface finishing effect and antiskid treatment. |

| 40-70# | High alloy steel casting surface oxide skin, aluminum alloy engine block and other large die casting parts cleaning and finishing, marble surface effect treatment and anti-skid treatment. |

| 70-140# 140-270# | The surface of the formed steel casting is deaerated before coating, automobile wheel hub, engine shell treatment, granite products and marble steps roughening and anti-skid treatment. |

Granularity

| ScreenNO. | Screensize mm | In | 14-18 | 16-20 | 20-25 | 25-30 | 30-40 | 40-70 | 70-140 | 140-270 |

| 14 | 1.4 | 0.0555 | ||||||||

| 16 | 1.18 | 0.0469 | ||||||||

| 18 | 1 | 0.0394 | ||||||||

| 20 | 0.85 | 0.0331 | ||||||||

| 25 | 0.71 | 0.0278 | ||||||||

| 30 | 0.6 | 0.0234 | ||||||||

| 35 | 0.5 | 0.0197 | ||||||||

| 40 | 0.425 | 0.0165 | ||||||||

| 50 | 0.3 | 0.0117 | ||||||||

| 70 | 0.212 | 0.0083 | ||||||||

| 100 | 0.15 | 0.0059 | ||||||||

| 140 | 0.106 | 0.0041 | ||||||||

| 270 | <0.05 | <0.0019 |

RECOMMEND PRODUCTS

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333