Steel Shot

-

Home >>Steel Shot & Grit >> Cast Steel Grit

Product description

Steel Shot is manufactured by melting selected scrap in electric induction furnace. The chemical composition of molten metal is analyzed and strictly controlled by spectrometer to obtain SAE Standard specification. The molten metal is atomized and transformed into round particle and subsequently quenched and tempered in a heat treating process to obtain a product of uniform hardness and microstructure, screened by size according to SAE Standard specification.

This type of shot is made for use in shot blasting and blasting processes under

pressure by compressed air. It is basically used on non-ferrous metals such as

aluminium, zinc alloys, stainless steels, bronze, brass, copper...

With its wide range of gradings, it is used for cleaning, deburring, compaction,

shot peening and general finishing processes, on all kinds of parts, without

contaminating its surface by ferrous dusts which deteriorate and change the

colour of the treated metals. It is ideal for the aging of marbles and granites.

Total quality controls are applied inspecting: grading, grain sphericity,

composition and resistance.

| Project | National Standards | Quality | |

| Chemical composition% | C | .85-1.20 | .85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Hardness | steel shot | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| Density | steel shot | ≥7.20 g/cm3 | 7.4g/cm3 |

| Microstructure | Tempered Martensite or Troostite | Tempered Martensite Bainite Composite organization | |

| Appearance | Spherical Hollow particles<10% Crack particle<15% | Spherical Hollow particles<5% Crack particle<10% | |

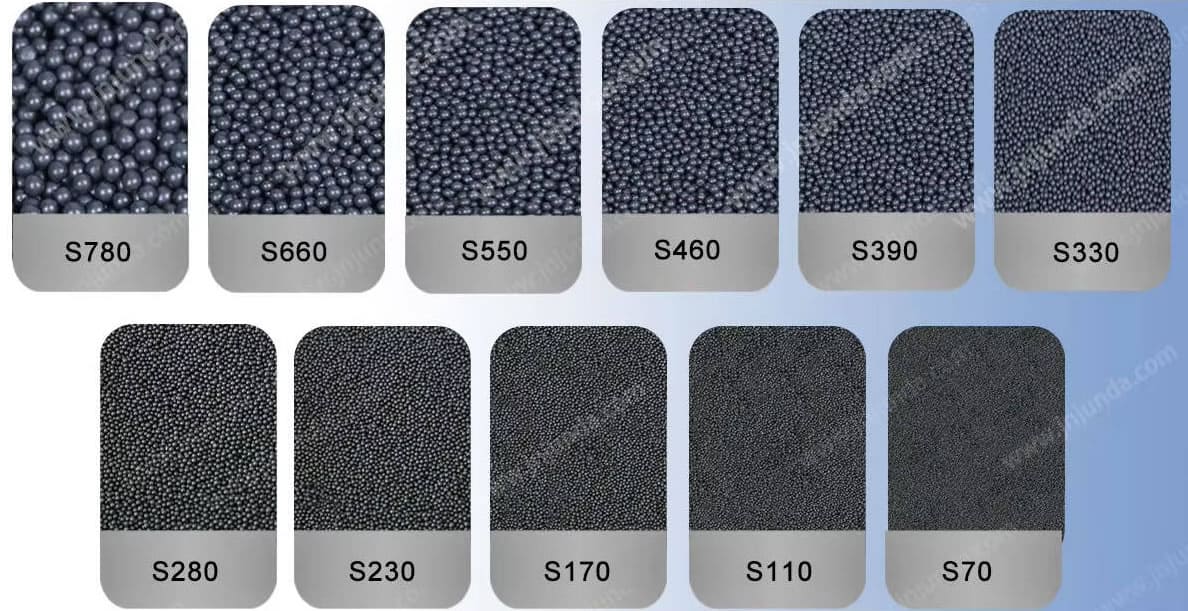

| Type | S70 ,S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Packing | Each ton in a separate Pallet and each ton divided in 25KG packs . | ||

| Durability | 2500~2800 times | ||

| Density | 7.4g/cm3 | ||

| .Diameter | 0.2mm,0.3mm,0.5mm,0.6mm,0.8mm,1.0mm,1.2mm,1.4mm,1.7mm,2.0mm,2.5mm | ||

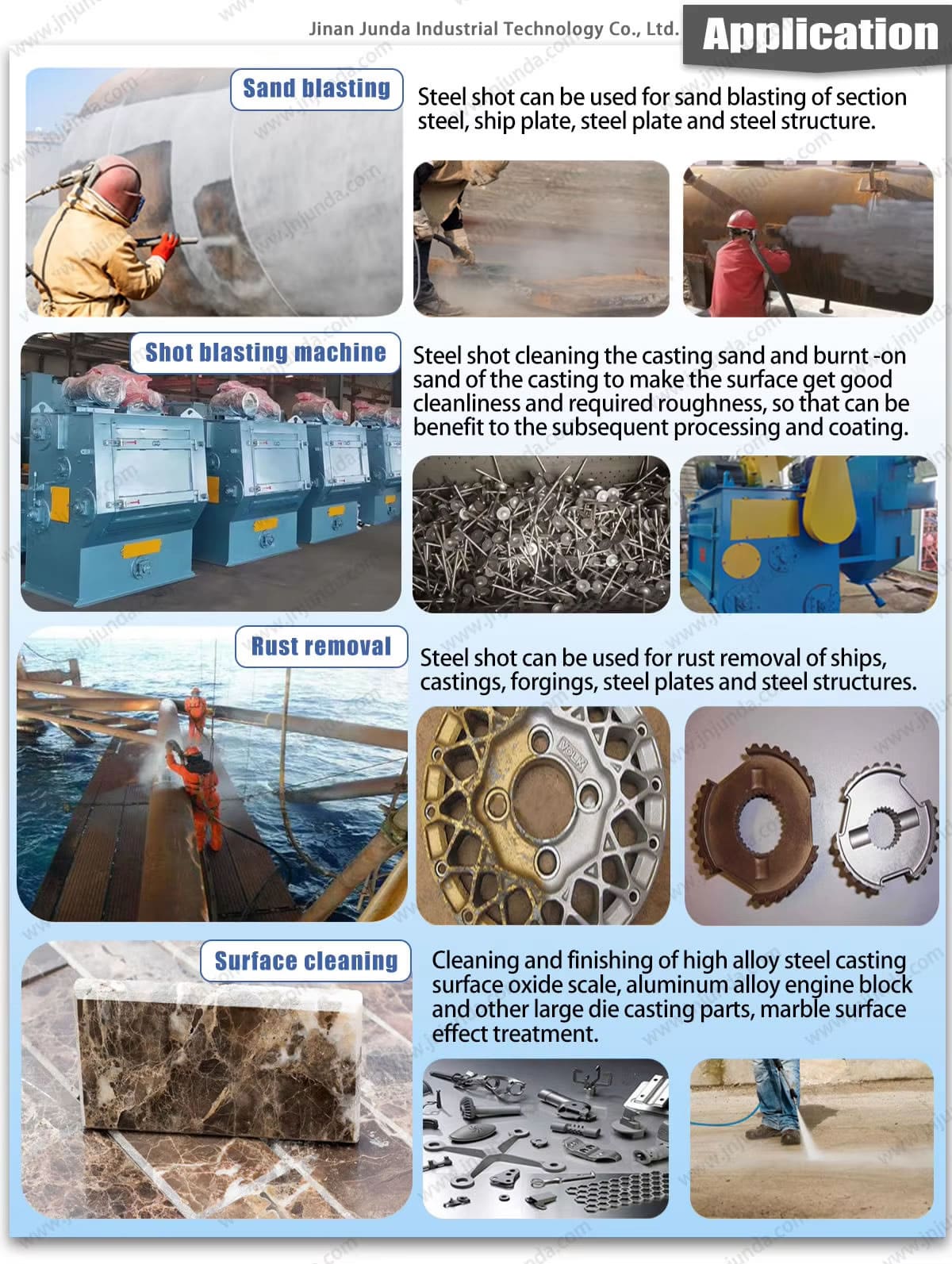

| Applications | 1.Blast

cleaning: Used for blast cleaning of casting, die-casting, forging;

sand removal of casting, steel plate, H type steel, steel structure. 2..Rust

removal: Rust removal of casting, forging, steel plate, H type

steel, steel structure. 3.Shot peening: Shot peening of gear, heat treated parts. 4.Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure. 5.Pre-treatment: Pre-treatment of surface, steel board, profile steel, steel structure, before painting or coating. | ||

| SIZE DISTRIBUTION OF STEEL SHOT | ||||||||||||||

| SAE J444 Standard Steel shot | Screen No. | In | Screen size | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| ALL pass | 6 | 0.132 | 3.35 | |||||||||||

| All Pass | 7 | 0.111 | 2.8 | |||||||||||

| 90% min | All Pass | 8 | 0.0937 | 2.36 | ||||||||||

| 97%min | 85%min | All Pass | Pass | 10 | 0.0787 | 2 | ||||||||

| 97%min | 85%min | 5% max | All Pass | 12 | 0.0661 | 1.7 | ||||||||

| 97%min | 85%min | 5% max | All Pass | 14 | 0.0555 | 1.4 | ||||||||

| 97%min | 85%min | 5% max | All Pass | 16 | 0.0469 | 1.18 | ||||||||

| 96%min | 85%min | 5% max | All Pass | 18 | 0.0394 | 1 | ||||||||

| 96%min | 85%min | 10% max | All Pass | 20 | 0.0331 | 0.85 | ||||||||

| 96%min | 85%min | 10% max | 25 | 0.028 | 0.71 | |||||||||

| 96%min | 85%min | All Pass | 30 | 0.023 | 0.6 | |||||||||

| 97%min | 10% max | 35 | 0.0197 | 0.5 | ||||||||||

| 85%min | All Pass | 40 | 0.0165 | 0.425 | ||||||||||

| 97%min | 10% max | 45 | 0.0138 | 0.355 | ||||||||||

| 85%min | 50 | 0.0117 | 0.3 | |||||||||||

| 90%min | 85%min | 80 | 0.007 | 0.18 | ||||||||||

| 90%min | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 4 | 0.3 | 0.2 | GB | ||

RECOMMEND PRODUCTS

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333