Glass Beads

-

Home >>Abrasive Media >> Copper Slag

Sandblasting Glass Beads

Junda glass bead is a type of abrasive blasting for surface finishing,

specifically to prepare metals by smoothing them. Bead blasting provides

superior surface cleaning to remove paint, rust and other coatings.

The glass bead blasting process is environment-friendly and chemical-free and

can be used to detect weld and solder flaws. Advantages of using glass bead

blasting include:

• A large variety of grades available for different jobs and profiles.

• Does not interfere with coatings as it isn't reactive.

• It leaves no residue or embedded contaminants, and also does not cause any

dimensional surface change.

• Improved corrosion resistance and the ability to smooth away surface flaws.

• No detectable crystalline silica.

How it works

Junda Glass bead blasting essentially applies fine glass beads of various sizes

at varying degrees of pressure. Smaller glass spheres result in a smoother

surface while larger spheres produce a more textured finish.

Glass beads do not remove any of the base metal or imbed the surface. It will

produce a better, more uniform finish while also adding sheen or brightness to

the part.

It has a variety of applications, including:

• Finishing: Can be used on a wide range of materials, including metals, glass,

plastic and rubber.

• Cleaning: Without causing a dimensional surface change, glass bead blasting

removes/cleans foreign substances.

• Deburring: In order to assemble and operate parts, corners and edges may need

to be deburred. Glass bead blasting can remove burrs and feathered edges while

ensuring no base metal from the surface is removed.

• Peening: Peening extends the life of metal parts by combating stress cracks

and corrosion.

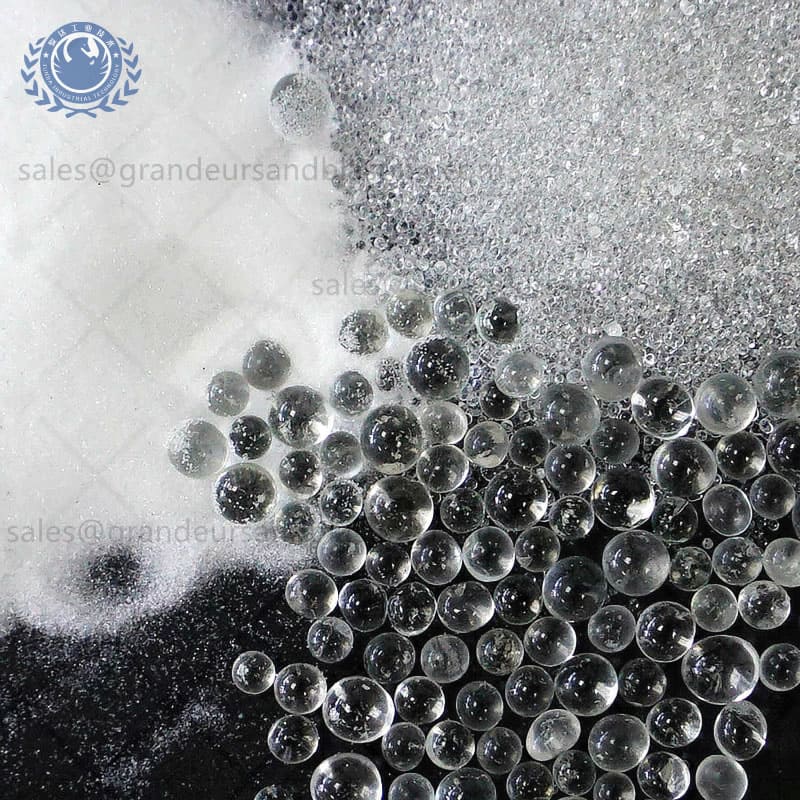

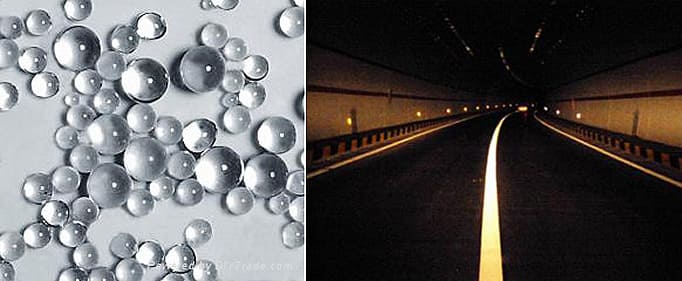

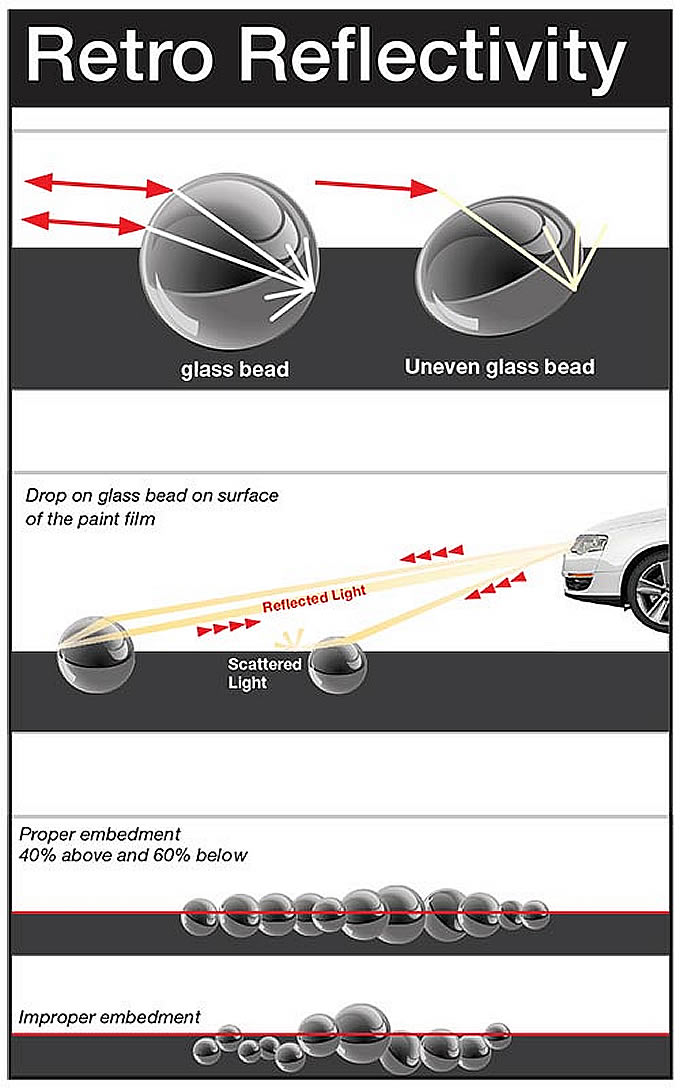

Glass beads for marking road surfaces

Junda Road marking glass bead is made from glass sand, waste glass as raw

material, after high temperature melting and formed a small glass beads, under

the microscope as spherical colorless transparent, diameter between 75 microns

to 1400 microns, currently in the main production of road reflective glass beads

process is flame floating method.

Junda Road marking glass beads are mainly used in normal temperature type, hot

melt type road marking coating, one as premixed material, can ensure the marking

in the life period of reflection, one in the marking construction surface

spread, can play a reflective effect.

Glass beads is used as a kind of high performance, organic material to outside

the glass beads, making glass beads weakened phenomenon of surface adsorption of

dust in the air, as a result of the glass beads containing specific coupling

agent, improved the beads and the cohesive force of coating can prevent some

tiny glass beads to the coating, because of its flotability function, when using

floating on the surface coating, It has a large surface area, can increase the

utilization rate of more than 30%, now reflective glass beads have become an

irreplaceable reflective material in road safety products.

We can provide glass beads with different refractive index of 1.53, 1.72, 1.93

and so on,We can also provide glass beads of various national standards, or

according to the size distribution provided by customers.

We provide the following standard glass beads

Chinese Standard: GB / T 24722 - 2009 No.1, 2, 3;

Korea Standard: KSL 2521 No.1 and 2;

British Standard : BS6088 Class A and B;

American Standard: AASHTO M247 type 1 and type 2;

European standard : EN1423 and EN1424;

Turkish Standard: TS EN1423;

New Zealand Standard: NZS2009: 2002;

Taiwan Standard : CNS;

Japanese standard : JIS R3301;

Australian Standard Australian Standard : A, B, C, D.

Grinding Glass Beads

Junda Grinding glass bead is a kind of glass bead with uniform size, smooth

surface, high hardness and good chemical stability. Grinding beads are generally

glass beads with a particle size greater than 1mm. They are colorless and

transparent in appearance and are a clean sphere. It is widely used in dye,

paint, ink, chemical industry and other dispersing agent, grinding medium and

filling materials.

We can provide 0.8 1.2, 1.0, 1.5, 1.5, 2.0, 2.0, 2.5, 2.5, 3.0, 3.0, 3.5 mm size

of these a few,

Also according to customer requirements.

application

1, bead strike aviation parts, eliminate its stress, to enhance fatigue

strength, and reduce friction and wear;

2, anodic treatment and electroplating before processing, in addition to

cleaning can increase adhesion;

3, stainless steel workpiece welding pass cleaning and surface scratch removal

and other aesthetic processing;

4. Cleaning and derusting of the wire cutting mould;

5, rubber mold descaling;

| Project | Quality | |

| Chemical composition% | SiO2 | >72% |

| CaO | >8% | |

| Na2O | <14% | |

| MgO | >2.5% | |

| Al2O3 | 0.5-2.0% | |

| Fe2O3 | 0.15% | |

| Others | 2.0% | |

| Refractive Index | Nd≥1.5% | |

| Density | 2.4-2.6g/cm3 | |

| Size distribution | Oversize ≤5% under size ≤10% | |

| Wire diameter | 0.03-0.4mm | |

| Durability | 3-5 % | |

| Hardness | 6-7 MOHS ;46HRC | |

| Microhardness | ≥650kg/cm3 | |

| Circularity | Round rate of ≥85% | |

| Appearance | colorless ,glass transparent without impurities,Round and smooth | |

| Application | 1.Grinding 2.Road marking paint 3.Sand blasting | |

| Lead Content | No lead content, reach American 16CFR 1303 Lead content standard | |

| Harmful substances content | Lower than American 16CFR 1500 standard | |

| Flammable fire test | Not easy combustion,reach American 16CFR 1500.44 standard | |

| Soluble heavy metal content | Metal content of soluble matter ratio solid weight rate no more than ASTM F963 corresponding value | |

| Package | 25KG/pp bag then 40 bags in one ton bag/pallet | |

Size

| Type | Mesh | Micronsm Max(μm) | Microns Min(μm) |

| 30# | 20-40 | 850 | 425 |

| 40# | 30-40 | 600 | 425 |

| 60# | 40-60 | 425 | 300 |

| 80# | 60-100 | 300 | 150 |

| 100# | 70-140 | 212 | 106 |

| 120# | 100-140 | 150 | 106 |

| 150# | 100-200 | 150 | 75 |

| 180# | 140-200 | 106 | 75 |

| 220# | 140-270 | 106 | 53 |

| 280# | 200-325 | 75 | 45 |

| 320# | >325 | 45 | 25 |

1. The production ways of glass beads

Glass beads are usually flame flotation method, the flame float method is a

secondary molding method, the basic principle of flame flotation method is to

break the waste glass into a certain size of the particles, and in a certain way

to the glass particles into the flame, In the role of the flame, the glass

particles soften, melting,molding, annealing then become glass beads.

2. quality control

A.raw materials

All raw materials are qualified products with product testing reports.

B. molding

In the production process, molding is the key of product quality . On the

furnace temperature control, the number of units and raw materials scattered

uniformity, the introduction of wind and other equipment in strict accordance

with the operating procedures.

C.annealing

annealing is the necessary way to improve the strength of the product, the

temperature is critical. We strictly according to set temperature, the annealing

speed can not be fast, nor slow, to ensure the timeliness of the annealing

process.

D.test

We use advanced detection equipment, to control the step quality , substandard

products can not be stored.

.

RECOMMEND PRODUCTS

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333