News

Characteristics and requirements of shot blasting in the aerospace field

3/7/2025

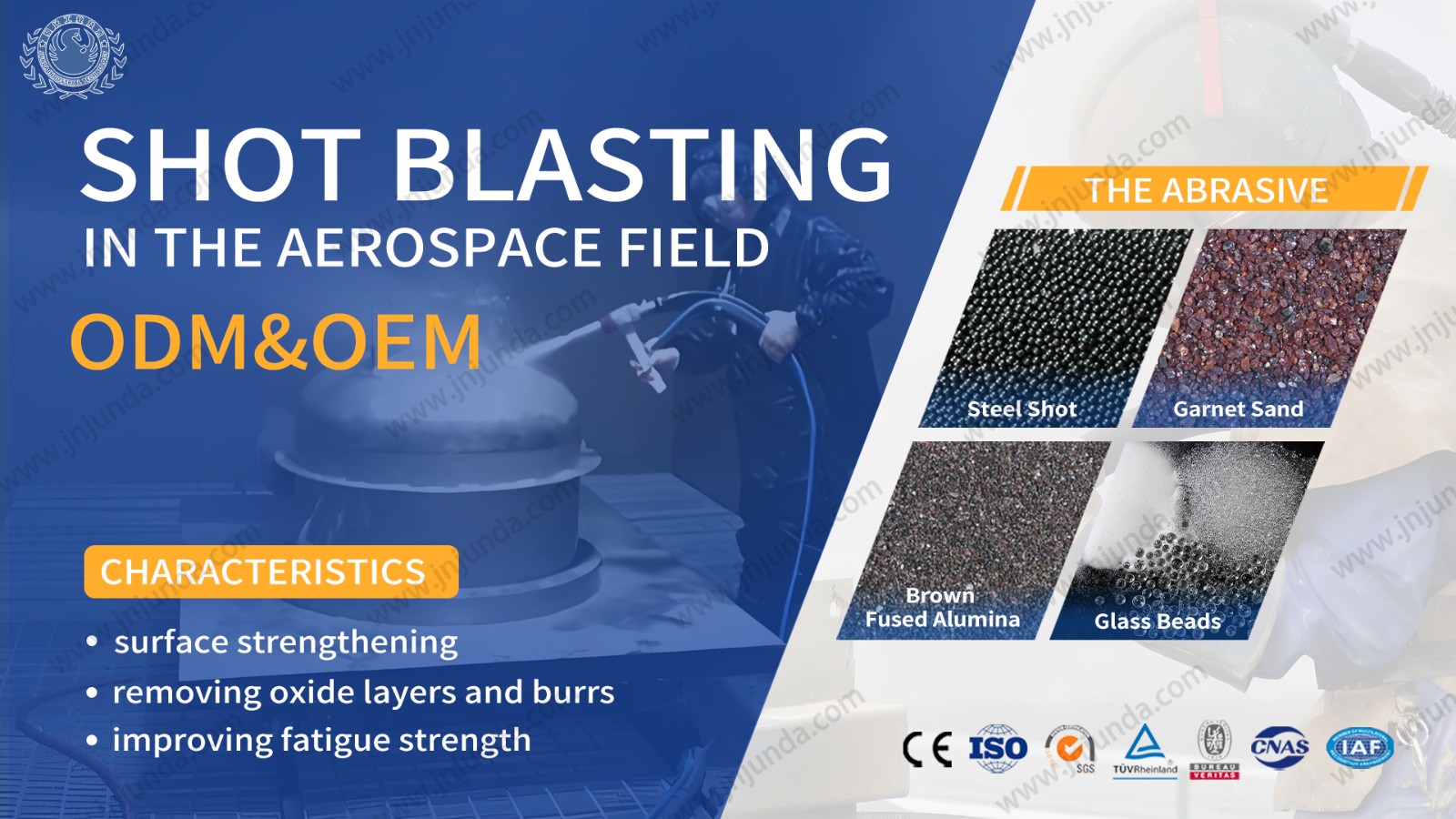

Shot blasting in the aerospace field has the characteristics of surface strengthening, removing oxide layers and burrs, and improving fatigue strength, and has strict requirements on shot type, processing parameters, surface quality, etc.

The main features and requirements of shot blasting in the aerospace field include:

Features:

I.Surface strengthening:

Shot blasting forms residual compressive stress on the surface of parts by high-speed shot blasting, thereby improving the fatigue strength and wear resistance of materials. II.Removing oxide layer and burrs:

Shot blasting can effectively remove oxide layer, burrs and impurities on the surface of parts, providing a good base for subsequent coating or bonding.

III.Improving surface roughness:

By adjusting the type of shot and processing parameters, the surface roughness can be precisely controlled to meet the design requirements of different parts.

IV.Increasing part life:

Shot blasting can eliminate surface defects and improve the fatigue life of materials, especially in aerospace parts that are subjected to high stress cycles.

V.Process controllability:

The shot blasting process can be adjusted according to the material, shape and performance requirements of the parts, and has good controllability.

Requirements:

I.Selection of shot:

The aerospace field usually uses high-hardness, high-strength, and pollution-free shot such as ceramic shot and stainless steel shot to meet the requirements for part surface quality and strength.

Control of processing parameters:

The speed, angle, coverage and other parameters of shot blasting need to be strictly controlled to ensure the consistency and repeatability of the processing effect.

II.Control of surface quality:

The surface of the treated parts needs to be strictly inspected for quality, including surface roughness, residual stress, oxide layer residue, etc., to ensure compliance with aerospace standards.

III.Equipment accuracy and stability:

Shot blasting equipment needs to have high accuracy and stability to ensure the accuracy and controllability of the processing process.

Environmental protection and safety:

Corresponding environmental protection measures need to be taken during the shot blasting process, such as dust removal, waste recycling, etc., and the safety of operators needs to be guaranteed.

In summary, shot blasting plays an important role in the aerospace field. It can effectively improve the surface performance of parts and extend their service life. But at the same time, there are strict requirements on the process parameters, equipment accuracy, shot material selection and quality control of shot blasting.

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333