News

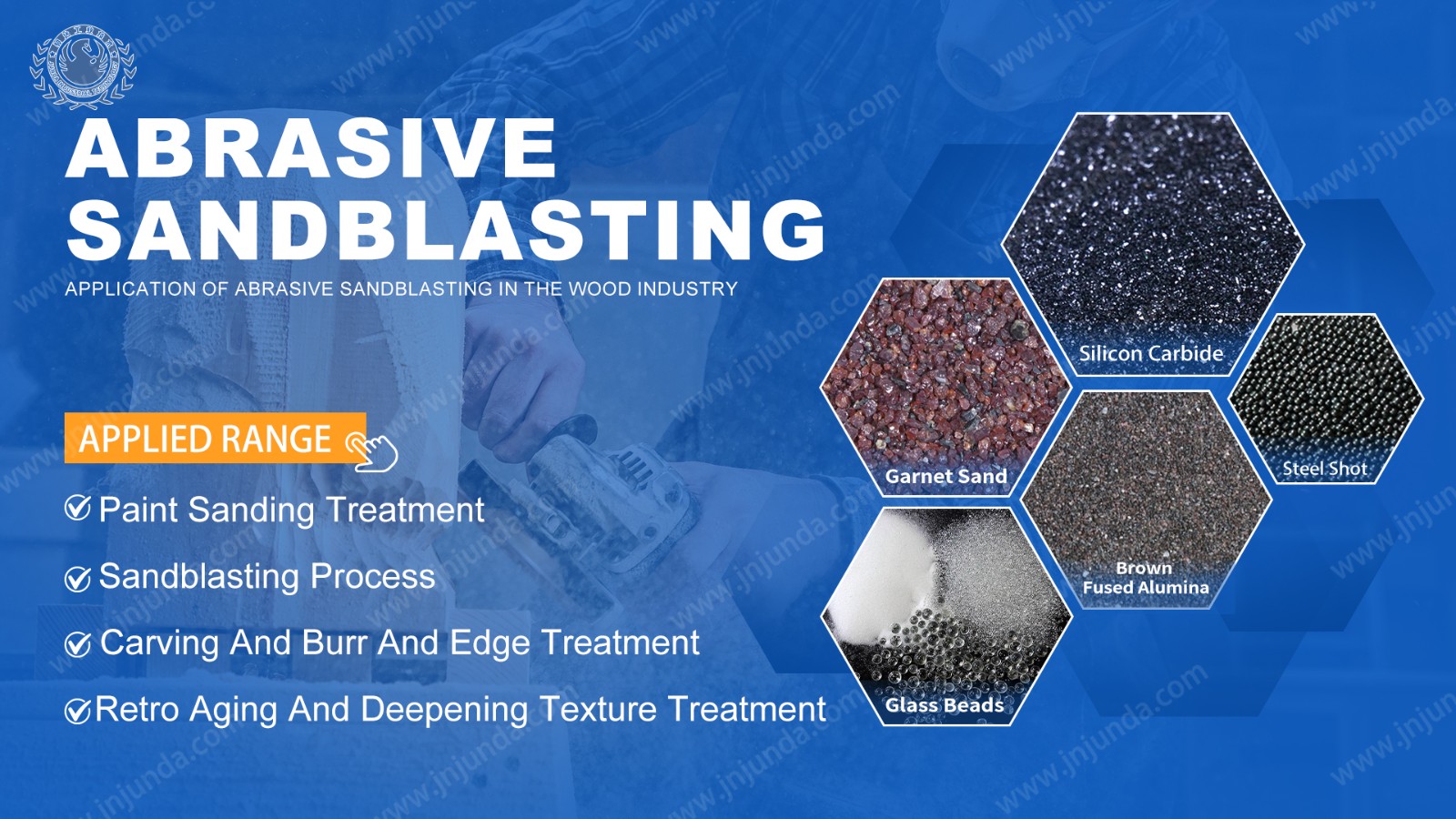

Application of abrasive sandblasting in the wood industry

26/6/2025

The wood sandblasting process can be widely used in the processing of wood surface and burr cleaning after carving, paint sanding, wood antique aging, furniture renovation, wood carving and other processes. It is used to improve the aesthetics of the wood surface, deep processing of wooden crafts and research on wood.

1. Retro aging and deepening texture treatment of wood and wood products

Wood has beautiful natural texture. After sandblasting, the early wood is concave into a groove shape, and the late wood is convex, realizing the beauty of wood texture and having a three-dimensional texture effect. It is suitable for furniture and indoor wall panels, which has a special three-dimensional artistic decorative effect.

2. Carving and burr and edge treatment of wood and wood products

Wooden carving crafts can highlight the three-dimensional sense of wood texture after full or partial sandblasting, thereby increasing the added value of the product. Using masking materials, shearing or cutting into various texts and patterns and pasting them on the material surface, after sandblasting, various texts and patterns can be displayed on the material surface. After the wood is spliced according to special textures and then sandblasted, a product with a special texture and three-dimensional decorative effect can be obtained.

3. Paint sanding treatment of wood products

Sandblasting removes burrs, floating rust, oil stains, dust, etc. on the surface of the base material; reduces the roughness of the painted surface of the workpiece, such as the surface after the putty is scraped and dried, the surface is generally rough and uneven, and it needs to be polished to obtain a smooth surface; enhance the adhesion of the paint. The adhesion of paint on smooth surfaces is poor, and sandblasting can enhance the mechanical adhesion of the paint.

Principle of wood sandblasting machine:

Sandblasting uses compressed air as a power to form a high-speed jet beam to spray the blasting media (copper ore sand, quartz sand, corundum or iron sand, garnet sand) at high speed onto the wood surface to be treated, so as to achieve the purpose of impacting and wearing the wood surface.

4. sandblasting process

When sandblasting, first place the wood in the sandblasting machine and fix it, then adjust the spray gun to 45°-60° tilt, and keep a distance of about 8cm from the surface of the workpiece, and spray continuously in the direction parallel to the wood texture or perpendicular to the wood texture to erode the wood surface and achieve the purpose of protruding the wood texture.

Features of wood sandblasting machine:

1. Abrasive recycling, low consumption and high efficiency.

2. Equipped with dust removal unit to effectively control dust pollution.

3. Equipped with double-layer observation glass, easy to replace.

4. The working cabin is fixed with a gun rack and a professional four-door design, which is convenient for wood and wooden products to enter. There are rollers inside to facilitate the movement of wood.

Advantages of sandblasting machine:

1. When the automatic sandblasting machine is used for sandblasting, the wood is basically not damaged and the dimensional accuracy will not change;

2. The wood surface is not polluted and the abrasive will not react chemically with the wood;

3. It can easily process grooves, concave and other difficult-to-reach parts, and abrasives of various particle sizes can be selected for use;

4. The processing cost is greatly reduced, which is mainly reflected in the improvement of work efficiency and can meet various surface finishing requirements;

5. Low energy consumption and cost saving;

6. No pollution to the environment, saving environmental governance costs;

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333