News

Garnet's Advantages in Replacing Quartz Sand

13/11/2025

1. Sandblasting,Rust Removal & Surface Treatment

- Reasons for Substitution:

- Environmental Protection: Quartz sand contains free silica, which can easily generate dust pollution during sandblasting. Long-term inhalation may cause silicosis. garnet sand does not contain free silica, meeting environmental standards, and can reduce occupational health risks.

- Safety: Quartz sand sandblasting may produce sparks, posing a safety hazard. Garnet sand is a natural non-metallic mineral and does not pose such a risk.

- Efficiency and Cost: Garnet sand has a higher hardness (7.5-8.5 vs. quartz sand 7). Its sharp, multi-faceted design improves sandblasting efficiency, saving 30% of abrasive material under the same conditions. It also has a longer service life and reduces overall costs.

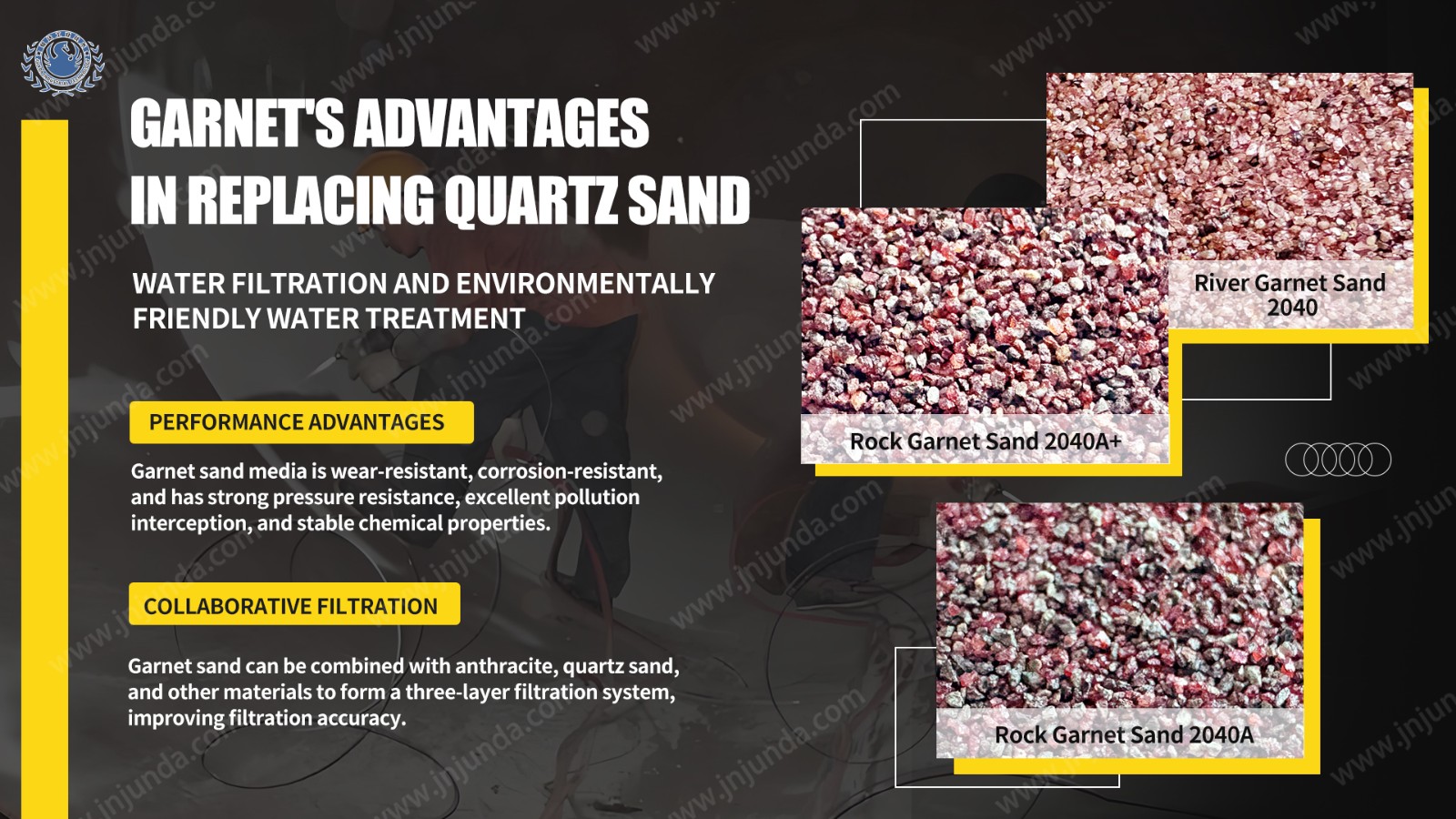

2. Water Filtration and Environmentally Friendly Water Treatment

- Performance Advantages: Garnet filter media is wear-resistant, corrosion-resistant, and has strong pressure resistance, excellent pollution interception, and stable chemical properties. It can be used as a water treatment filter medium in the chemical, petroleum, and pharmaceutical industries. The particle size range is 0.25-5.0mm. - Collaborative Filtration: It can be combined with anthracite, quartz sand, and other materials to form a three-layer filtration system. Placed beneath the quartz sand layer, it serves as the final water quality control step, improving filtration accuracy.

3. Precision Manufacturing and High-End Applications

- Cutting and Grinding: Garnet sand has high hardness and excellent toughness, making it suitable for cutting, grinding, and polishing in high-end applications such as spacecraft, aircraft manufacturing, and shipbuilding. Replacing quartz sand can improve machining accuracy and surface quality.

- Coated Abrasives: The global coated abrasives market is growing rapidly. As a high-performance abrasive, garnet sand can meet the demand for high-end products in developed industrial countries, driving the industry's development towards precision.

4. Long-Term Trend of Substituting Traditional Abrasives

- Policy and Market Drivers:

- Environmental Pressure: Stricter global environmental policies are restricting the use of quartz sand due to pollution concerns. As an environmentally friendly natural abrasive, garnet sand continues to gain market share.

- Economical: Garnet sand is recyclable and has a lower long-term cost than quartz sand, meeting the needs of industrial manufacturing to reduce costs and increase efficiency.

Any further details you need, please feel free contact.

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

Building A.B.C ,Ouyadaguan Commercial Capital, No.67 Yangguang Xin Road, Shizhong District,Jinan City, Shandong Province, China

0086-531-82020205

+0086-15806668333