News

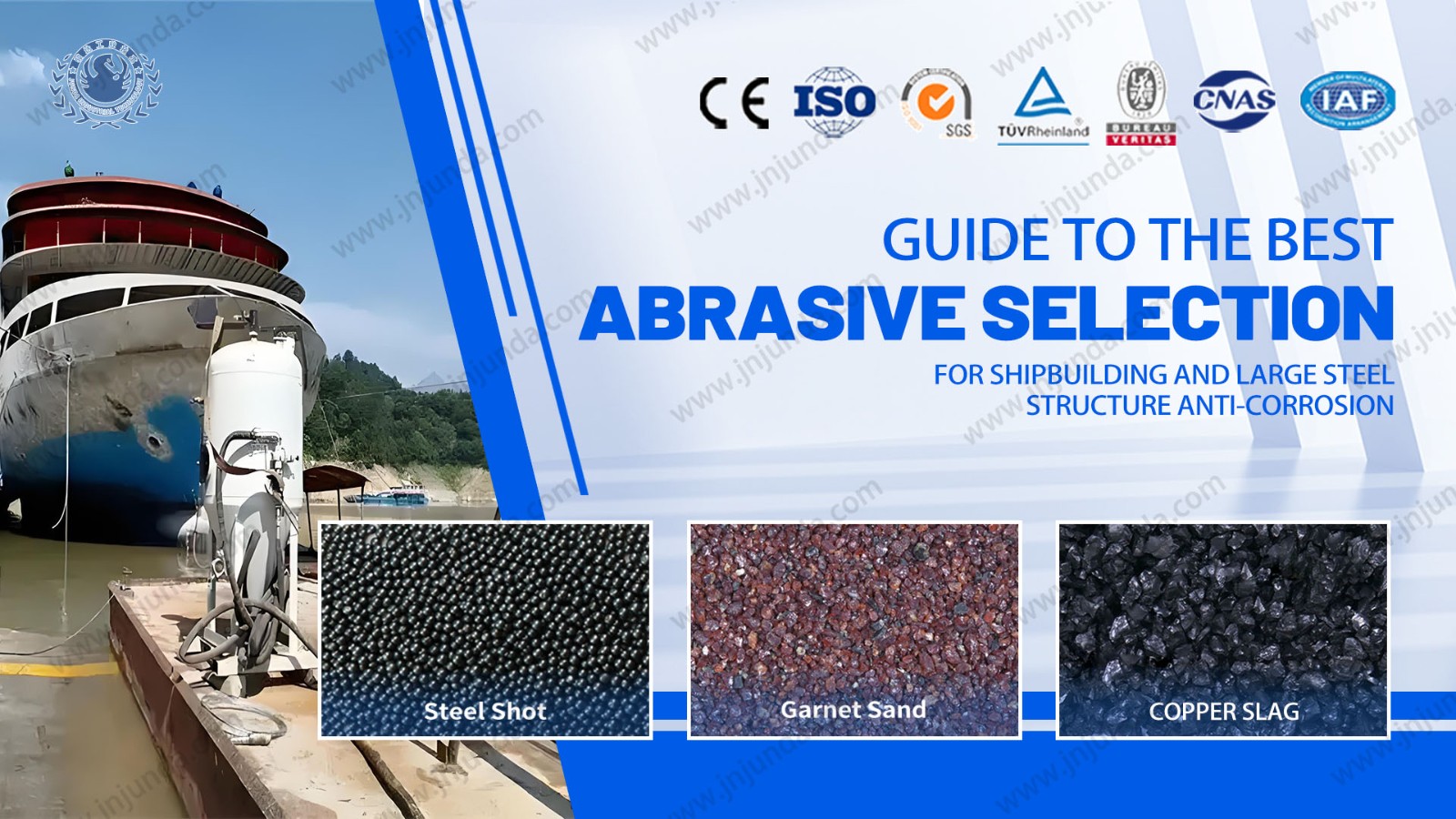

Guide to the best abrasive selection for shipbuilding and large steel structure anti-corrosion projects

31/7/2025

In shipbuilding and large steel structure anti-corrosion projects, the selection of abrasives needs to be combined with factors such as rust removal efficiency, surface quality, environmental protection and cost. The advantages and applicable scenarios of different abrasives are significantly different, as follows:

- Applicable scenarios: pretreatment of non-load-bearing components (such as railings, brackets) and temporary transition coatings in shipbuilding (rust removal level Sa2.0 is sufficient), no deep anchor pattern is required; short-term anti-corrosion projects (lifespan within 10 years) of large steel structures (such as factory steel columns, ordinary storage tanks), or projects with limited budgets.

Steel shot/steel sand:"extreme in performance"; garnet sand :"extreme in environmental protection";copper slag : "extreme in cost", which correspond to the different requirements of "high requirements for key parts, environmentally sensitive areas, and low cost for non-key parts" in the project.

Any further details you need, please feel free contact.

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333