News

Water jet cutting

2/8/2021

Water jet cutting can be divided into 2 categories:

1. Water Jet Cutting

2. Abrasive Water Jet Cutting

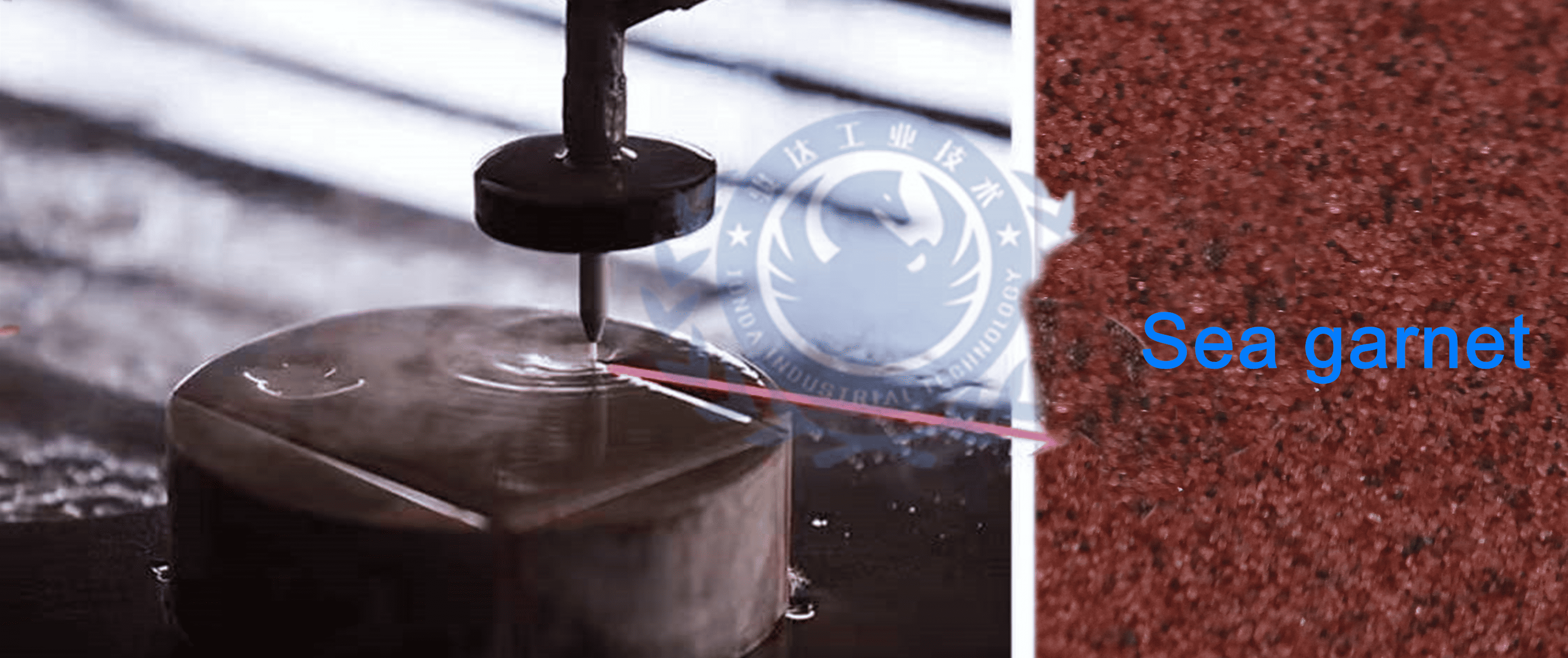

Both of the procedures require the water to be pumped to a pressure of up to 6000 bar, which is subsequently released via a nozzle, generating a high speed water jet.

Water Jet Cutting uses this jet as a tool to cut soft materials like foam, textiles or food.

Abrasive(garnet sand)water jet cuttting

When applying Abrasive Water Jet Cutting, an abrasive material(garnet sand) is subsequently added to the water jet and accelerated in a focusing tube. The resulting abrasive water jet is able to cut all common technical materials, such as:

·steel and stainless steel

·aluminum, non-ferrous metals and noble metals

·chromium, nickel, titanium, tantalum etc.

·hard metals

·ceramics

·glass, armoured glass

·rock, granite, marble

·sandwich materials, structural materials, reinforced plastics (CFK, GFK)

·thermoplasts and duroplastics

1. Water Jet Cutting

2. Abrasive Water Jet Cutting

Both of the procedures require the water to be pumped to a pressure of up to 6000 bar, which is subsequently released via a nozzle, generating a high speed water jet.

Water Jet Cutting uses this jet as a tool to cut soft materials like foam, textiles or food.

Abrasive(garnet sand)water jet cuttting

When applying Abrasive Water Jet Cutting, an abrasive material(garnet sand) is subsequently added to the water jet and accelerated in a focusing tube. The resulting abrasive water jet is able to cut all common technical materials, such as:

·steel and stainless steel

·aluminum, non-ferrous metals and noble metals

·chromium, nickel, titanium, tantalum etc.

·hard metals

·ceramics

·glass, armoured glass

·rock, granite, marble

·sandwich materials, structural materials, reinforced plastics (CFK, GFK)

·thermoplasts and duroplastics

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333

-

Message