News

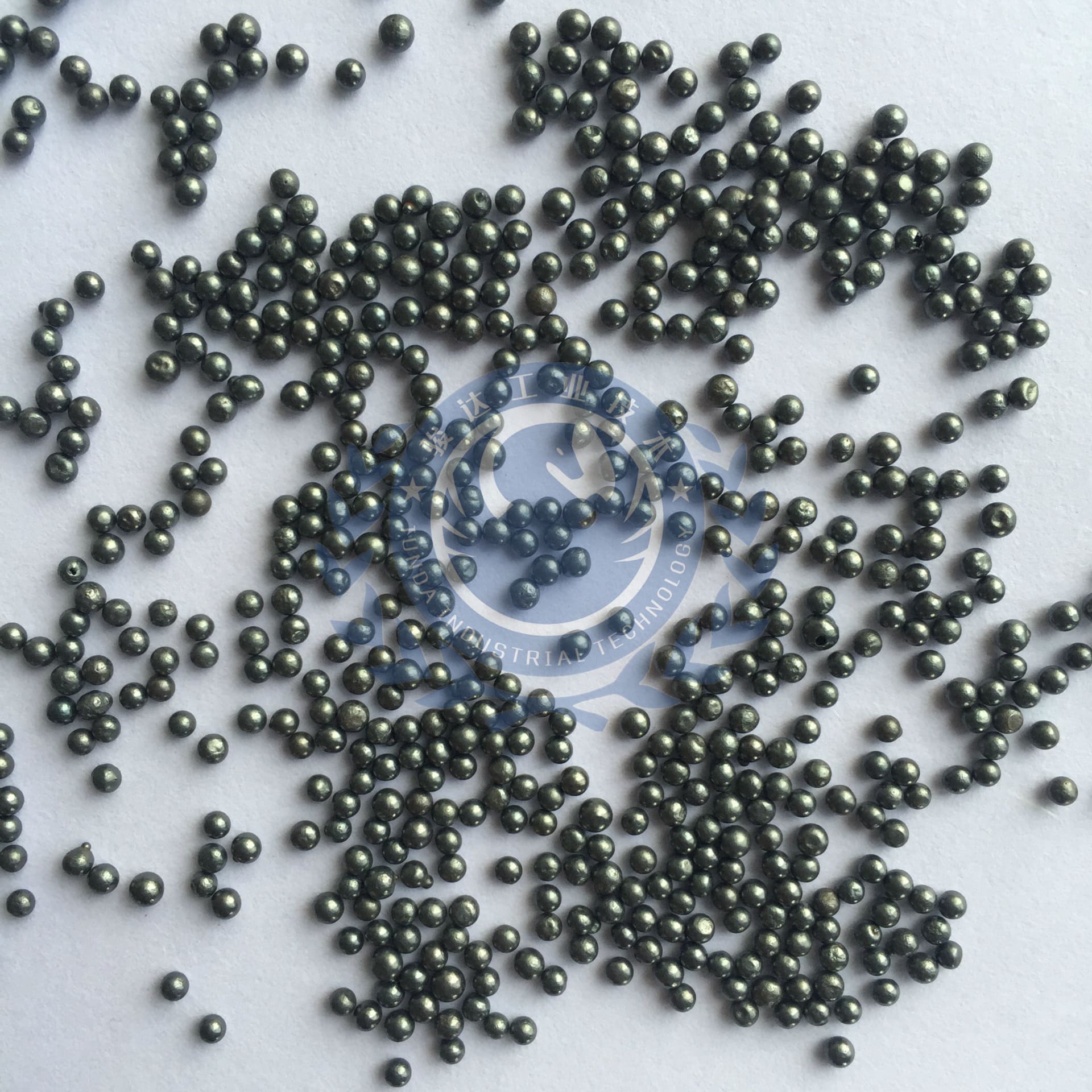

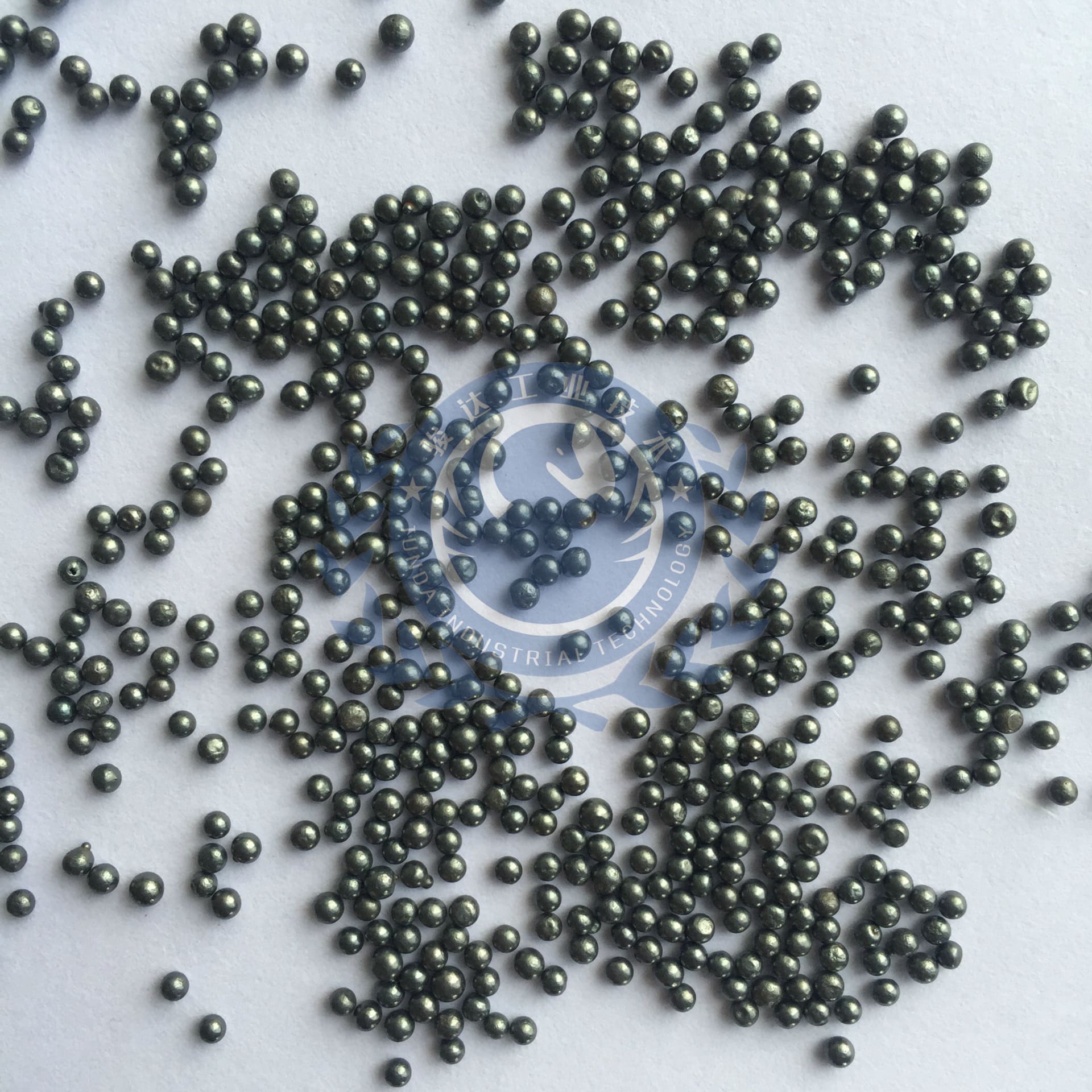

Selection of steel shot - particle size

27/7/2021

When selecting the particle size of steel shot, on the premise of meeting the requirements of surface roughness, larger steel shot shall be selected as far as possible to improve the cleaning efficiency. Graded steel shot is preferred. The graded steel shot is composed of about 50% nominal size steel shot and gradually smaller steel shot. Taking into account the impact force and coverage, it can obtain the highest cleaning efficiency and lower surface roughness (compared with the steel shot with single particle size).

In the production process, each steel shot is a process of continuous wear and reduction, so the particle size of each steel shot is constantly changing. Because the hot spot changes with the change of steel shot particle size, in order to ensure that the hot particle size / RAM matching gradually tends to the normal curve. If too much material is added at one time, the casting surface will become rough immediately; Without feeding for a long time, although the surface quality of the casting is improved, the cleaning efficiency will be greatly reduced.

In the production process, each steel shot is a process of continuous wear and reduction, so the particle size of each steel shot is constantly changing. Because the hot spot changes with the change of steel shot particle size, in order to ensure that the hot particle size / RAM matching gradually tends to the normal curve. If too much material is added at one time, the casting surface will become rough immediately; Without feeding for a long time, although the surface quality of the casting is improved, the cleaning efficiency will be greatly reduced.

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333

-

Message