News

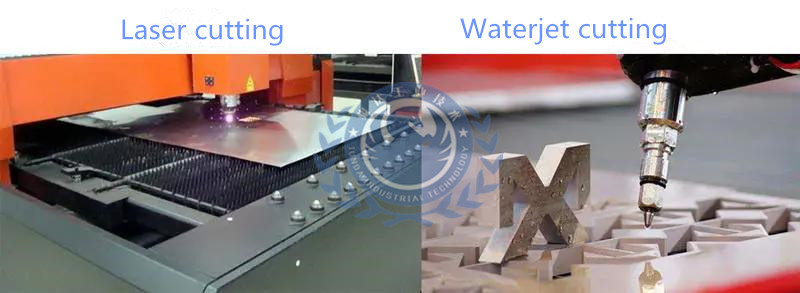

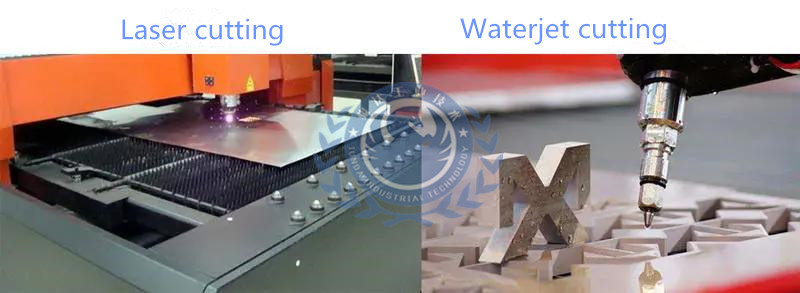

Waterjet vs. Laser

16/8/2021

•Waterjets can machine any materials that lasers cannot. Reflective materials in particular, such as aluminum and copper.

•There is no thermal distortion or edge hardening of the material being cut by waterjet, whereas lasers create burned, hardened edges.

•Precision waterjets can obtain about the same tolerances as lasers on thin parts, and higher tolerances on parts thicker than 0.5".

•Waterjets do not lose much focus when cutting over uneven surfaces, lasers do.

•Waterjets create much cleaner edge quality.

•Fast turn-around.

•There is no thermal distortion or edge hardening of the material being cut by waterjet, whereas lasers create burned, hardened edges.

•Precision waterjets can obtain about the same tolerances as lasers on thin parts, and higher tolerances on parts thicker than 0.5".

•Waterjets do not lose much focus when cutting over uneven surfaces, lasers do.

•Waterjets create much cleaner edge quality.

•Fast turn-around.

professional firm engaged in the research, development, sale, and service of Steel Shot, Steel Grit, sandblaster, sandblasting machine, garnet sand. We are located in Jinan with convenient transportation access. .

Quick links

Products Structure

Our Contacts

No.365 ,The Second Jing Road ,Huaiyin District, Jinan City ,Shandong Province ,China

0086-531-82020205

+0086-15806668333

-

Message